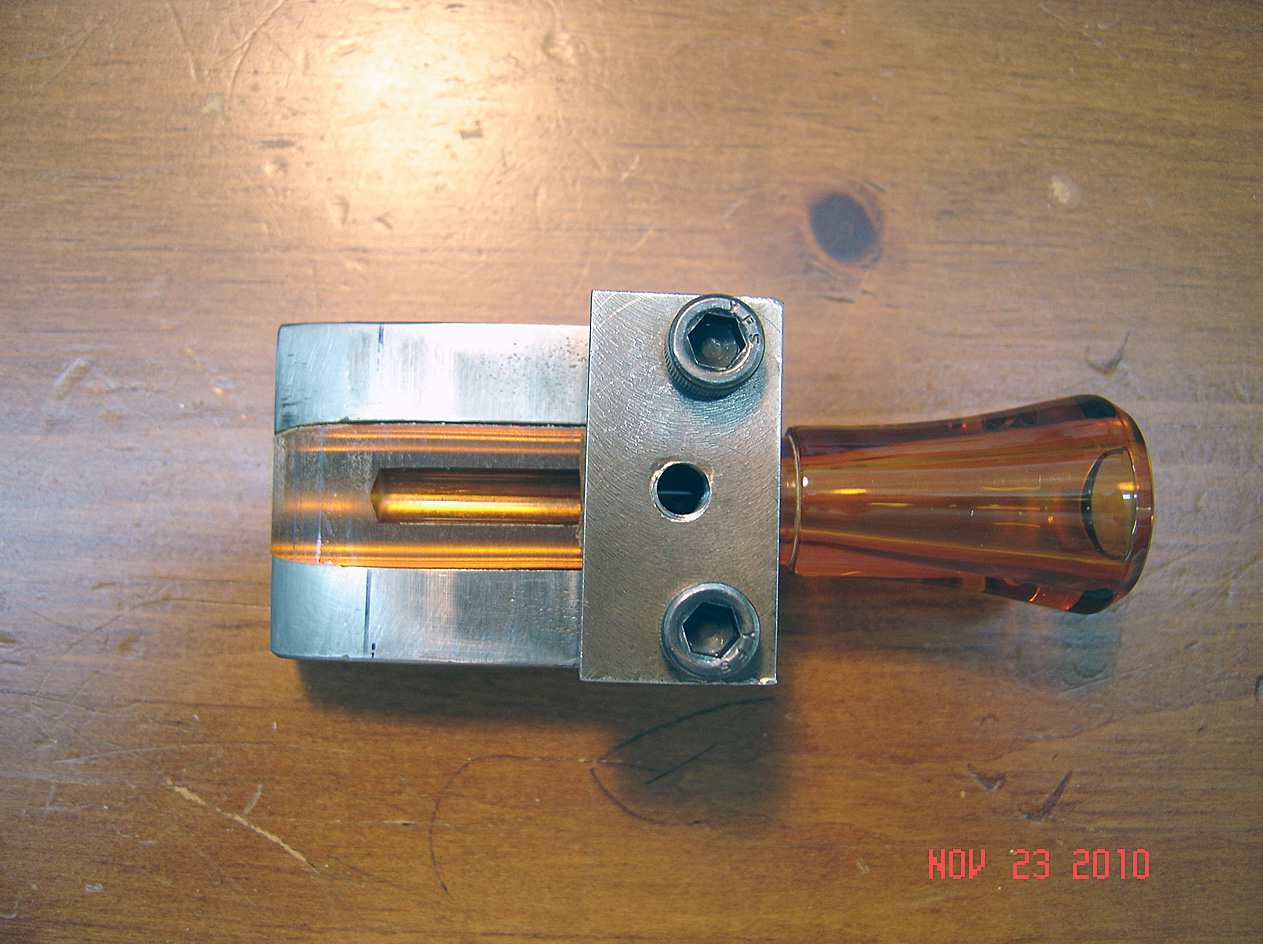

We decided to put up some of the specs to help callmakers using our jig, troubleshoot any issues they may be having. While we have very few issues with out jig, 99% of the issues are with the call locking up. These issues usually pertain to having too small of an exhaust port or minor sanding.

Exhaust port (Fig A) . Our calls use a large exhaust port of 1/2″. These taper down to 1/4″ of the course of 1.5″ (fig C)

Drill depth stops exactly 1/2″ before the end of the toneboard (Fig B)

Our reed are cut at a 45 degree angle on the end (Fig D)

Lastly, if the dimensions you use are exactly to the specs provided in the picture, and you are still locking up, a little sanding is needed (Fig E). A very light (1000 grit) sanding is usually all the needs to be done. This is usually done from the end of the toneboard in the undrilled area (Fig B) and roughly 1/4″ under the reed. The sharp cut at the end of the toneboard can also be rounded over a bit. Another trick, is to run your thumb, under the reed to 'flex' it up just a hair to help get enough air under the reed.

Duck Call Insert 3-PACK SPECIAL - World Champion Refuge Calls Big Bore Polycarb Double Reed Inserts DUCKSUSA. From shop DUCKSUSA. 3.5 out of 5 stars (219) 219 reviews $ 21.87. Favorite Add to Handcrafted Acrylic Duck Call with Echo reed insert McCutchwoodworks. From shop McCutchwoodworks. Custom Jigs (1) Duck Call Jigs (7) Goose Gut Jigs (0) Machined Blanks; Mandrels. Blind Type (1) Stepped Diameter Expanding Mandrels (4) Straight Expanding Mandrels (13).

If you have tried at making your own custom call jig out of wood or plastic or whatever and it didn't work out as planned and you are ready to get a custom jig made, we offer various ways to go about this. We can take your CADD files or custom toneboard in either wood, acrylic, or delrin and by use of a shadowgraph, make a digital copy of your toneboard. This allows us to get a perfect radius for perfect duplications.

Once your jig is completed, we will send it off to heat treat where they harden it to 60 rc for years of use. Since our jigs are made in two pieces, the distortion during hardening is VERY minimal. Once piece jigs tend to twist more due to being an L shape. This also allows for easier cutting and in turn a lower cost for our customers. We are able to heat treat our jigs before cutting if you desire this, but you really are just wasting money.

Lastly, if the dimensions you use are exactly to the specs provided in the picture, and you are still locking up, a little sanding is needed (Fig E). A very light (1000 grit) sanding is usually all the needs to be done. This is usually done from the end of the toneboard in the undrilled area (Fig B) and roughly 1/4″ under the reed. The sharp cut at the end of the toneboard can also be rounded over a bit. Another trick, is to run your thumb, under the reed to 'flex' it up just a hair to help get enough air under the reed.

Duck Call Insert 3-PACK SPECIAL - World Champion Refuge Calls Big Bore Polycarb Double Reed Inserts DUCKSUSA. From shop DUCKSUSA. 3.5 out of 5 stars (219) 219 reviews $ 21.87. Favorite Add to Handcrafted Acrylic Duck Call with Echo reed insert McCutchwoodworks. From shop McCutchwoodworks. Custom Jigs (1) Duck Call Jigs (7) Goose Gut Jigs (0) Machined Blanks; Mandrels. Blind Type (1) Stepped Diameter Expanding Mandrels (4) Straight Expanding Mandrels (13).

If you have tried at making your own custom call jig out of wood or plastic or whatever and it didn't work out as planned and you are ready to get a custom jig made, we offer various ways to go about this. We can take your CADD files or custom toneboard in either wood, acrylic, or delrin and by use of a shadowgraph, make a digital copy of your toneboard. This allows us to get a perfect radius for perfect duplications.

Once your jig is completed, we will send it off to heat treat where they harden it to 60 rc for years of use. Since our jigs are made in two pieces, the distortion during hardening is VERY minimal. Once piece jigs tend to twist more due to being an L shape. This also allows for easier cutting and in turn a lower cost for our customers. We are able to heat treat our jigs before cutting if you desire this, but you really are just wasting money.

Duck Call Insert Jig Dimensions

After heat treating, our jigs are double checked for tolerances, sandblasted and cleaned up, checked for burs in the threads, and have new hardware installed before being shipped to you!